Tablet Press Troubleshooting for Uneven Tablet Weight

Introduction

Uneven tablet weight is a common issue encountered during tablet compression, affecting product quality, consistency, and compliance with regulatory standards. Variations in tablet weight can lead to dosage inaccuracies, poor dissolution, and potential batch rejections. This guide provides a comprehensive troubleshooting approach to identify and resolve the root causes of uneven tablet weight in tablet presses.

---

1. Understanding Tablet Weight Variation

Before troubleshooting, it is essential to understand the factors influencing tablet weight:

- Material Properties: Poor flowability, inconsistent particle size, or moisture content can lead to uneven filling of die cavities.

- Machine Settings: Incorrect compression force, turret speed, or feeder settings can cause weight variations.

- Tooling Issues: Worn or misaligned punches and dies can result in inconsistent tablet formation.

- Environmental Conditions: Humidity and temperature fluctuations may affect powder properties.

- Feeding System Problems: Uneven powder feed can lead to inconsistent die filling.

---

2. Step-by-Step Troubleshooting Guide

2.1. Check Powder Properties

2.1.1. Flowability Issues

- Symptoms: Poor powder flow leads to inconsistent die filling.

- Solutions:

- Optimize granulation to improve flow (e.g., adjust binder concentration).

- Use glidants (e.g., colloidal silicon dioxide) to enhance powder flow.

- Ensure proper drying to prevent agglomeration.

2.1.2. Particle Size Distribution

- Symptoms: Segregation or inconsistent packing density in the die.

- Solutions:

- Conduct sieve analysis to ensure uniform particle size.

- Adjust milling or granulation parameters if needed.

- Avoid excessive fines, which can cause bridging in the hopper.

2.1.3. Moisture Content

- Symptoms: Powder sticking or erratic flow due to moisture.

- Solutions:

- Monitor and control humidity in the compression area.

- Ensure proper drying of granules before compression.

- Use desiccants if necessary.

---

2.2. Evaluate Machine Settings

2.2.1. Feeder System Issues

- Symptoms: Uneven powder feed into dies.

- Solutions:

- Adjust feeder paddle speed to ensure consistent powder delivery.

- Check for blockages or powder buildup in the hopper.

- Ensure the feeder is properly aligned with the turret.

2.2.2. Turret Speed

- Symptoms: Weight variation due to insufficient die filling time.

- Solutions:

- Reduce turret speed to allow proper powder settling.

- Test different speeds to find the optimal setting.

2.2.3. Compression Force

- Symptoms: Over-compression can lead to weight variation due to elastic recovery.

- Solutions:

- Adjust compression force to ensure uniform tablet hardness without over-pressing.

- Monitor tablet weight and hardness correlation.

---

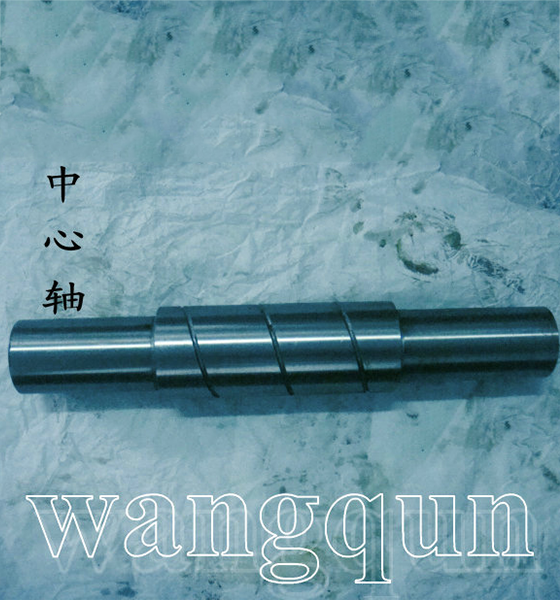

2.3. Inspect Tooling (Punches & Dies)

2.3.1. Worn or Damaged Dies

- Symptoms: Uneven tablet weight due to inconsistent die filling.

- Solutions:

- Inspect dies for wear, scoring, or deformation.

- Replace damaged dies to ensure uniform cavity dimensions.

2.3.2. Punch Length Variation

- Symptoms: Different tablet weights due to inconsistent punch penetration.

- Solutions:

- Measure punch lengths and replace mismatched punches.

- Ensure uniform punch tip condition.

2.3.3. Misaligned Tooling

- Symptoms: Uneven compression due to misalignment.

- Solutions:

- Verify punch and die alignment.

- Check turret alignment and tighten loose components.

---

2.4. Environmental & Operational Factors

2.4.1. Humidity & Temperature

- Symptoms: Powder clumping or sticking due to moisture.

- Solutions:

- Maintain controlled humidity levels (ideally 40-60% RH).

- Use dehumidifiers if necessary.

2.4.2. Static Electricity

- Symptoms: Powder clinging to surfaces, causing inconsistent flow.

- Solutions:

- Use anti-static additives or ionizers.

- Ground the tablet press to dissipate static charges.

---

2.5. Additional Checks

2.5.1. Hopper Level

- Symptoms: Inconsistent powder feed due to low hopper levels.

- Solutions:

- Maintain an adequate powder level in the hopper.

- Avoid overfilling, which can lead to bridging.

2.5.2. Machine Calibration

- Symptoms: Inconsistent tablet weight due to calibration drift.

- Solutions:

- Regularly calibrate the tablet press.

- Verify weight control mechanisms (e.g., load cells).

---

3. Preventive Measures

To minimize tablet weight variation:

1. Optimize Formulation: Ensure good flowability and compressibility.

2. Regular Maintenance: Inspect tooling and machine components frequently.

3. Process Validation: Conduct periodic checks on compression parameters.

4. Operator Training: Ensure staff are trained in proper machine operation.

5. Environmental Control: Maintain stable humidity and temperature.

---

4. Conclusion

Uneven tablet weight is a multifactorial issue requiring systematic troubleshooting. By examining powder properties, machine settings, tooling condition, and environmental factors, manufacturers can identify and rectify the root causes. Implementing preventive measures ensures consistent tablet quality and compliance with industry standards. Regular monitoring and maintenance are key to minimizing weight variations in tablet production.

---

This guide provides a structured approach to troubleshooting tablet weight issues, helping manufacturers achieve uniform tablet production. If problems persist, consulting technical experts or conducting further process optimization may be necessary.

Teléfono

Teléfono

Comentario

(0)