Rotary Tablet Press Safety Features Explained

Introduction

Rotary tablet presses are widely used in the pharmaceutical, nutraceutical, and chemical industries to produce tablets of uniform size, weight, and hardness. Given the high-speed operation and mechanical complexity of these machines, ensuring operator safety and preventing equipment damage is critical. Modern rotary tablet presses incorporate multiple safety features designed to protect personnel, maintain product quality, and comply with industry regulations.

This article provides a detailed explanation of the key safety features found in rotary tablet presses, covering mechanical, electrical, and operational safeguards.

---

1. Mechanical Safety Features

1.1. Guarding and Interlocks

One of the most fundamental safety measures is the use of physical guards and interlocking mechanisms. These prevent access to moving parts such as the turret, punches, and dies during operation.

- Fixed Guards: Permanent barriers enclose hazardous areas, preventing accidental contact.

- Interlocked Guards: These are connected to the machine’s control system. If a guard is opened while the press is running, the machine immediately stops to prevent injury.

- Magnetic or Proximity Sensors: Ensure that guards are securely closed before operation can resume.

1.2. Emergency Stop (E-Stop) Buttons

Emergency stop buttons are strategically placed around the machine for quick access. When pressed:

- The machine halts immediately.

- Power to motors and actuators is cut.

- A manual reset is required to restart, ensuring no accidental reactivation.

1.3. Punch and Die Protection

Punches and dies are critical components that must be protected from damage due to misalignment or excessive force.

- Overload Protection: Sensors detect excessive compression force and stop the machine to prevent punch breakage.

- Punch Withdrawal Safety: Prevents jamming by ensuring punches retract properly after compression.

- Automatic Punch Lubrication: Reduces friction and wear, minimizing the risk of punch sticking or breakage.

1.4. Turret Locking Mechanism

The turret must remain stable during operation. Safety features include:

- Hydraulic or Pneumatic Locks: Secure the turret in place to prevent rotation when not in use.

- Turret Alignment Sensors: Ensure proper positioning before operation begins.

---

2. Electrical Safety Features

2.1. Motor Protection

Motors driving the rotary press must be safeguarded against overheating and electrical faults.

- Thermal Overload Relays: Cut power if the motor exceeds safe temperature limits.

- Phase Failure Protection: Prevents damage due to unbalanced power supply.

- Variable Frequency Drives (VFDs): Allow smooth acceleration and deceleration, reducing mechanical stress.

2.2. Ground Fault Protection

Electrical faults can pose serious hazards. Safety measures include:

- Ground Fault Circuit Interrupters (GFCIs): Detect leakage current and shut off power to prevent shocks.

- Insulation Monitoring: Ensures wiring and components remain safe from short circuits.

2.3. Control System Safety

Modern tablet presses use programmable logic controllers (PLCs) with built-in safety functions.

- Dual-Channel Safety Circuits: Require two independent signals to confirm safe operation.

- Fail-Safe Design: If a sensor or control component fails, the system defaults to a safe shutdown.

---

3. Operational Safety Features

3.1. Pressure Monitoring

Tablet compression force must be controlled to ensure consistent quality and prevent machine damage.

- Force Sensors: Monitor compression in real-time and adjust or stop the machine if limits are exceeded.

- Automatic Rejection: Defective tablets are ejected if they do not meet predefined weight or hardness criteria.

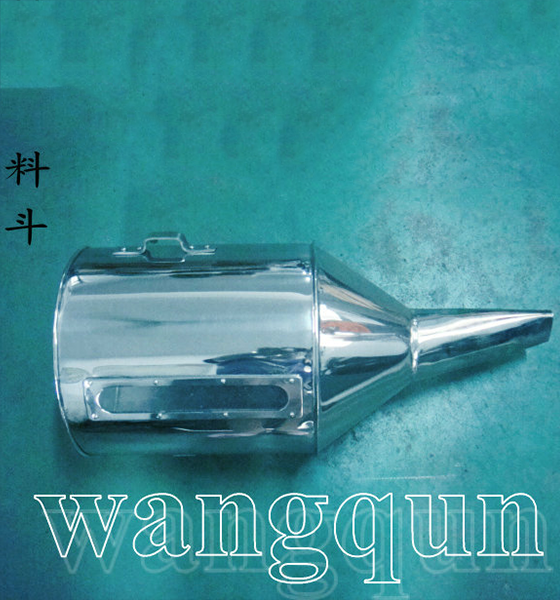

3.2. Material Feed Safety

Uneven or insufficient granule feed can cause tablet defects or machine jams.

- Hopper Level Sensors: Ensure adequate material supply before operation.

- Feed Frame Sensors: Detect blockages or irregular flow, triggering alarms or shutdowns if necessary.

3.3. Noise and Vibration Control

Excessive noise and vibration can indicate mechanical issues or pose ergonomic risks.

- Vibration Dampeners: Reduce machine oscillations.

- Acoustic Enclosures: Minimize noise exposure for operators.

---

4. Compliance with Safety Standards

Rotary tablet presses must adhere to international safety regulations, including:

- ISO 13849 (Safety of Machinery): Defines performance levels for safety-related control systems.

- CE Marking (Europe): Ensures compliance with EU health and safety directives.

- OSHA (USA): Mandates workplace safety measures for industrial machinery.

---

5. Best Practices for Safe Operation

Even with advanced safety features, proper training and maintenance are essential.

- Operator Training: Ensure personnel understand safety protocols and emergency procedures.

- Regular Inspections: Check guards, sensors, and interlocks for proper function.

- Preventive Maintenance: Lubricate moving parts, replace worn components, and update software as needed.

---

Conclusion

Rotary tablet presses incorporate multiple safety features to protect operators, maintain product quality, and comply with industry standards. From mechanical guards and emergency stops to advanced electrical and operational safeguards, these systems work together to minimize risks. By following best practices and adhering to safety regulations, manufacturers can ensure efficient and accident-free tablet production.

Understanding these safety features is crucial for operators, maintenance personnel, and engineers working with rotary tablet presses. Continuous advancements in automation and sensor technology will further enhance safety in the years to come.

Teléfono

Teléfono

Comentario

(0)