Large Tonnage Tablet Press Operational Troubleshooting Guide

Introduction

Large tonnage tablet presses are critical in pharmaceutical, nutraceutical, and chemical industries for producing high-volume, high-density tablets. These machines operate under significant pressure and require precise mechanical and process control to ensure consistent tablet quality. However, operational issues such as sticking, capping, weight variation, and machine wear can arise, leading to production delays and product defects.

This guide provides comprehensive troubleshooting tips for common problems encountered in large tonnage tablet press operations, focusing on mechanical, process-related, and material-related issues.

---

1. Common Tablet Defects and Solutions

1.1 Capping and Lamination

Symptoms:

- Tablet separates into layers (lamination) or breaks at the top (capping).

- Occurs during compression or ejection.

Possible Causes & Solutions:

- Excessive Compression Force: Reduce compression force or adjust pre-compression settings.

- Insufficient Binder in Formulation: Increase binder concentration or optimize granulation.

- Air Entrapment: Improve powder flow or use deaeration techniques.

- Punch Wear or Misalignment: Inspect and replace worn punches or dies.

- Moisture Content: Ensure proper drying of granules before compression.

1.2 Sticking and Picking

Symptoms:

- Material adheres to punch faces, causing surface defects.

Possible Causes & Solutions:

- Poor Lubrication: Increase lubricant concentration (e.g., magnesium stearate).

- High Moisture Content: Dry granules to optimal moisture levels.

- Rough Punch Surface: Polish or replace damaged punches.

- Excessive Compression Force: Reduce compression pressure.

- Insufficient Anti-adherent: Add colloidal silica or talc to the blend.

1.3 Weight Variation

Symptoms:

- Inconsistent tablet weights, leading to dosage inaccuracies.

Possible Causes & Solutions:

- Poor Powder Flow: Optimize granule size distribution or add glidants (e.g., silicon dioxide).

- Feeder Inconsistency: Adjust feeder speed or check for blockages.

- Die Fill Variation: Ensure uniform die filling by optimizing turret speed.

- Punch Length Variation: Check and replace worn punches.

- Machine Vibration: Stabilize the press or isolate from external vibrations.

1.4 Chipping and Cracking

Symptoms:

- Tablets chip at edges or develop cracks after ejection.

Possible Causes & Solutions:

- High Ejection Force: Adjust ejection settings or apply additional lubrication.

- Brittle Formulation: Modify excipients to improve tablet strength.

- Improper Die Chamfer: Inspect and replace damaged dies.

- Excessive Turret Speed: Reduce press speed to minimize stress during ejection.

---

2. Mechanical and Operational Issues

2.1 Excessive Noise or Vibration

Symptoms:

- Unusual grinding, knocking, or excessive vibration during operation.

Possible Causes & Solutions:

- Misaligned Turret or Tooling: Realign turret and check punch/die alignment.

- Worn Bearings or Bushings: Replace damaged bearings or bushings.

- Loose Bolts or Fasteners: Tighten all mechanical connections.

- Unbalanced Tooling: Ensure punches and dies are evenly distributed.

2.2 Punch and Die Wear

Symptoms:

- Increased tablet defects, rough edges, or sticking.

Possible Causes & Solutions:

- Abrasive Formulation: Use hardened tooling or increase lubricant.

- Improper Cleaning: Regularly clean punches and dies to prevent residue buildup.

- Excessive Compression Force: Optimize compression settings.

- Poor Maintenance: Follow scheduled tooling inspections and replacements.

2.3 Hydraulic or Pneumatic System Failures

Symptoms:

- Loss of pressure, slow operation, or inconsistent compression.

Possible Causes & Solutions:

- Hydraulic Fluid Leak: Inspect seals and hoses; refill or replace fluid.

- Clogged Filters: Clean or replace hydraulic/pneumatic filters.

- Faulty Pressure Regulator: Calibrate or replace regulators.

- Air Entrapment in Hydraulic System: Bleed air from the system.

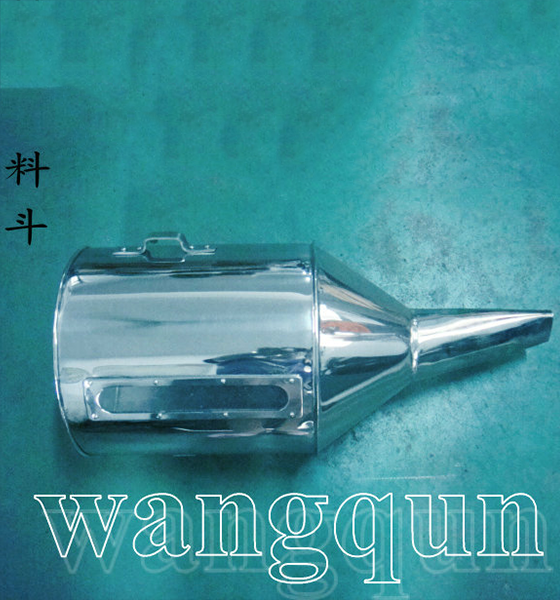

2.4 Feeder System Issues

Symptoms:

- Uneven powder flow, bridging, or incomplete die filling.

Possible Causes & Solutions:

- Powder Bridging: Use agitators or force feeders to improve flow.

- Incorrect Feeder Speed: Adjust feeder speed to match turret rotation.

- Material Segregation: Optimize blending to prevent ingredient separation.

- Blockages: Clean feeder hopper and chutes regularly.

---

3. Process Optimization and Preventive Maintenance

3.1 Regular Machine Inspection

- Daily Checks:

- Verify lubrication levels.

- Inspect punches and dies for wear.

- Check hydraulic/pneumatic pressure.

- Weekly/Monthly Maintenance:

- Clean and calibrate sensors.

- Inspect belts, bearings, and motors.

- Verify alignment of turret and tooling.

3.2 Tooling Management

- Proper Storage: Store punches and dies in a dry, controlled environment.

- Rotation Schedule: Rotate tooling to distribute wear evenly.

- Polishing & Coating: Use anti-wear coatings to extend tool life.

3.3 Operator Training

- Ensure operators understand:

- Correct machine setup.

- Troubleshooting common defects.

- Importance of preventive maintenance.

---

Conclusion

Large tonnage tablet presses require meticulous attention to mechanical, process, and material factors to maintain efficiency and tablet quality. By identifying common defects early and implementing corrective actions, manufacturers can minimize downtime and ensure consistent production. Regular maintenance, proper tooling care, and operator training are essential for long-term operational success.

Following these troubleshooting guidelines will help optimize tablet press performance, reduce waste, and enhance product quality in high-volume tablet manufacturing.

Teléfono

Teléfono

Comentario

(0)