Large Tonnage Tablet Press for High-Capacity Production Plants

Introduction

The pharmaceutical and nutraceutical industries rely heavily on tablet presses to produce large quantities of tablets efficiently. A large tonnage tablet press is designed for high-capacity production plants, offering superior performance, durability, and precision. These machines are engineered to handle high compression forces while maintaining consistent tablet quality, making them ideal for large-scale manufacturing.

This article explores the key features, working principles, advantages, and applications of large tonnage tablet presses in high-capacity production environments.

---

1. Overview of Large Tonnage Tablet Presses

Large tonnage tablet presses are heavy-duty machines capable of producing millions of tablets per hour. They are designed to withstand high compression forces (typically ranging from 50 kN to over 100 kN per station) while ensuring uniformity in tablet weight, hardness, and thickness.

Key Characteristics:

- High Production Capacity: Capable of producing 500,000 to over 1,000,000 tablets per hour.

- Robust Construction: Built with high-strength materials to endure continuous operation.

- Multi-Station Tooling: Equipped with multiple punch stations (e.g., 55, 75, or more) to maximize output.

- Advanced Control Systems: Integrated automation for real-time monitoring and adjustments.

- Flexibility: Compatible with various tablet shapes, sizes, and formulations.

---

2. Working Principle of Large Tonnage Tablet Presses

The operation of a large tonnage tablet press follows a systematic process:

Step 1: Powder Feeding

- Granulated powder is fed into the die cavity via a feed frame.

- The feed system ensures uniform distribution to avoid weight variations.

Step 2: Compression

- Upper and lower punches compress the powder under high pressure (up to 100+ kN).

- The compression force is precisely controlled to ensure tablet integrity.

Step 3: Ejection

- The lower punch rises to eject the formed tablet from the die.

- A take-off blade guides the tablet out of the compression zone.

Step 4: Tablet Discharge

- The finished tablet is conveyed to a collection system or packaging line.

This cycle repeats continuously, allowing for high-speed production.

---

3. Key Components of a Large Tonnage Tablet Press

A. Compression Unit

- Turret: Rotates to position punches and dies for compression.

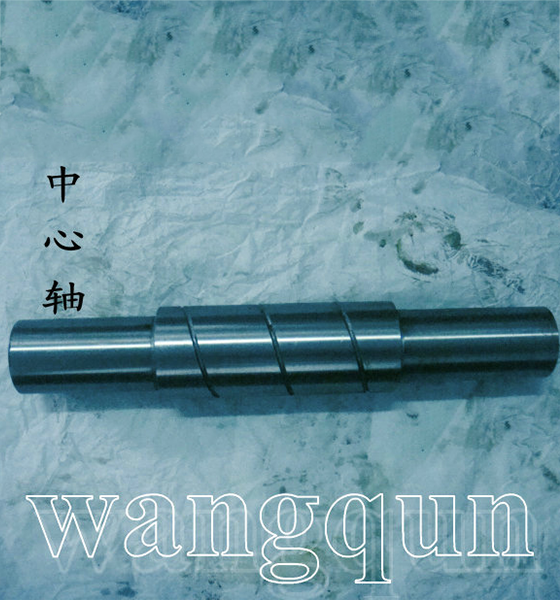

- Punches & Dies: High-grade steel tooling designed for durability and precision.

- Pre-Compression & Main Compression Rollers: Ensure uniform tablet density.

B. Feeding System

- Feed Frame: Distributes powder evenly into dies.

- Force Feeder: Enhances powder flow for high-speed operation.

C. Control & Monitoring System

- HMI (Human-Machine Interface): Allows operators to adjust parameters.

- Pressure Sensors: Monitor compression force in real time.

- Weight & Thickness Control: Ensures tablet consistency.

D. Lubrication & Cooling System

- Automatic Lubrication: Reduces wear on moving parts.

- Cooling Mechanism: Prevents overheating during prolonged operation.

---

4. Advantages of Large Tonnage Tablet Presses

A. High Efficiency & Productivity

- Capable of producing millions of tablets per shift.

- Reduces production time and labor costs.

B. Consistent Tablet Quality

- Precise control over weight, hardness, and thickness.

- Minimizes batch-to-batch variations.

C. Durability & Reliability

- Designed for 24/7 operation in demanding environments.

- Low maintenance requirements due to robust construction.

D. Flexibility in Formulation

- Handles a wide range of powders, granules, and formulations.

- Supports multiple tablet shapes (round, oval, capsule-shaped, etc.).

E. Compliance with Regulatory Standards

- Meets GMP (Good Manufacturing Practices) and FDA requirements.

- Easy to clean and validate for pharmaceutical use.

---

5. Applications in High-Capacity Production Plants

Large tonnage tablet presses are widely used in:

A. Pharmaceutical Industry

- Mass production of OTC and prescription tablets.

- High-volume manufacturing of vitamins and supplements.

B. Nutraceutical & Dietary Supplements

- Production of multivitamins, minerals, and herbal tablets.

C. Industrial Applications

- Manufacturing of detergent tablets, effervescent tablets, and agrochemicals.

---

6. Selection Criteria for Large Tonnage Tablet Presses

When choosing a tablet press for high-capacity production, consider:

A. Production Requirements

- Desired output (tablets per hour).

- Tablet size and shape specifications.

B. Machine Specifications

- Number of punch stations.

- Maximum compression force.

C. Automation & Control Features

- Real-time monitoring capabilities.

- Integration with other production line equipment.

D. Maintenance & Serviceability

- Ease of cleaning and tooling changeover.

- Availability of spare parts and technical support.

---

7. Future Trends in Large Tonnage Tablet Press Technology

A. Increased Automation & AI Integration

- Predictive maintenance using AI-driven analytics.

- Self-adjusting compression parameters for optimal performance.

B. Energy Efficiency Improvements

- Reduced power consumption through advanced motor systems.

C. Enhanced Material Handling

- Improved powder feeding mechanisms to minimize waste.

D. Smart Manufacturing (Industry 4.0)

- IoT-enabled tablet presses for remote monitoring.

- Data-driven optimization of production processes.

---

8. Conclusion

Large tonnage tablet presses are indispensable in high-capacity production plants, offering unparalleled efficiency, precision, and reliability. With advancements in automation and smart manufacturing, these machines continue to evolve, meeting the growing demands of the pharmaceutical and nutraceutical industries.

Investing in a high-performance tablet press ensures consistent tablet quality, regulatory compliance, and long-term cost savings, making it a critical asset for large-scale manufacturers.

---

This comprehensive guide provides an in-depth understanding of large tonnage tablet presses, their benefits, and their role in modern high-capacity production facilities. If you require further details on specific models or technical specifications, consulting industry experts is recommended.

Teléfono

Teléfono

Comentario

(0)