Optimizing Feeder Systems in Large Tonnage Tablet Presses

Introduction

Feeder systems play a critical role in large tonnage tablet presses, ensuring consistent powder flow, accurate dosing, and uniform tablet quality. As tablet production scales up to meet growing pharmaceutical and nutraceutical demands, optimizing feeder systems becomes essential for maintaining productivity, minimizing waste, and ensuring regulatory compliance. This comprehensive guide explores key strategies for optimizing feeder systems in high-capacity tablet pressing operations.

Understanding Feeder System Components

Before optimization, it's crucial to understand the main components of feeder systems in large tonnage presses:

1. Hopper Design: The primary reservoir holding the powder formulation

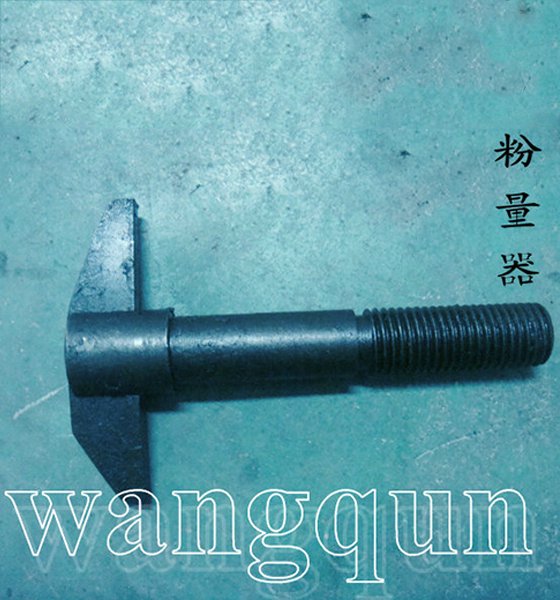

2. Feeding Mechanism: Screw feeders, rotary feeders, or vibratory feeders that transport material

3. Flow Aids: Devices to prevent bridging or rat-holing (vibrators, agitators, air bladders)

4. Control Systems: Sensors and software regulating feed rate and consistency

5. Interface with Compression Zone: How material transitions from feeder to die table

Each component presents unique optimization opportunities that collectively improve system performance.

Material Characterization for Optimal Feeding

Particle Size Analysis

Conduct thorough particle size distribution analysis using laser diffraction or sieve analysis. Optimal feeding typically requires:

- D50 between 50-200 microns for most formulations

- Minimal fines (particles <20 microns) to prevent segregation

- Narrow distribution for consistent flow

Flow Property Assessment

Measure key powder flow parameters:

- Angle of Repose: Ideal range 25-40 degrees

- Compressibility Index: Target <20% for good flow

- Shear Cell Testing: Determines cohesive strength and wall friction

Moisture Sensitivity Evaluation

Assess how humidity affects flow characteristics. Many powders become more cohesive with moisture absorption, requiring:

- Environmental controls in feeding area

- Desiccant systems for moisture-sensitive APIs

- Special hopper coatings to minimize moisture effects

Hopper Design Optimization

Geometry Considerations

- Conical vs. Planar Flow: Conical hoppers suit free-flowing materials while planar flow designs better handle cohesive powders

- Wall Angles: Must exceed the material's wall friction angle by 5-10 degrees

- Transition Sections: Smooth transitions between hopper and feeder prevent stagnation zones

Surface Treatments

- Electropolishing: Reduces surface roughness to <0.4 μm Ra

- Special Coatings: PTFE, chrome oxide, or proprietary nano-coatings minimize adhesion

- Mirror Finishes: For extremely sticky formulations

Capacity Balancing

- Minimum Hold-up: 1.5-2x the feeder's maximum discharge rate

- Maximum Fill Level: Maintain 20-30% headspace to allow powder movement

- Live Bottom Design: Active discharge systems for problematic materials

Feeder Mechanism Selection and Tuning

Screw Feeder Optimization

For volumetric screw feeders:

- Pitch Design: Variable pitch screws handle different flow regimes

- Trough Loading: Maintain 30-70% fill for consistent delivery

- Speed Control: Optimize RPM to match press speed while avoiding flooding

For loss-in-weight screw feeders:

- Dosing Accuracy: Target ±0.5-1% of set point

- Refresh Rate: Control system should update at least 10x per screw revolution

- Vibration Isolation: Prevent external vibrations from affecting load cells

Rotary Feeder Adjustments

- Pocket Design: Match pocket volume to desired dose

- Clearances: 0.1-0.3mm between rotor and housing

- Purge Systems: Air knives or vacuum to clean pockets between rotations

Vibratory Feeder Tuning

- Frequency Adjustment: Typically 50-100Hz for pharmaceutical powders

- Amplitude Control: 0.5-3mm stroke for gentle material movement

- Tray Design: Stepped or coated surfaces to prevent material buildup

Advanced Flow Assistance Technologies

Aeration Systems

- Microporous Membranes: Even air distribution through hopper walls

- Pulsed Air: Timed bursts prevent channeling

- Fluidization Control: Maintain optimal powder mobility without flooding

Mechanical Agitation

- Sweeping Arms: 1-5 RPM with flexible wipers

- Reciprocating Bars: 5-15mm stroke at 0.5-2Hz

- Vibrating Disks: Low amplitude, high frequency under powder bed

Electrostatic Control

- Ionized Air Systems: Neutralize static charges

- Grounding Systems: <10 ohm resistance to earth

- Humidification: Maintain 40-60% RH when compatible with formulation

Process Integration and Control

Feed Rate Synchronization

- Closed-loop Control: Real-time adjustment based on tablet weight signals

- Lead Compensation: Account for system lag times (typically 0.5-2 seconds)

- Press Speed Tracking: Adaptive feed rate algorithms for variable speed operation

Material Tracking Systems

- RFID Tags: Track material lots through feeding system

- Vision Systems: Monitor powder surface levels and flow patterns

- Mass Flow Meters: Verify actual throughput against setpoints

Predictive Maintenance

- Wear Monitoring: Track screw/rotor clearance changes over time

- Vibration Analysis: Detect bearing wear or imbalance early

- Performance Trending: Identify gradual efficiency declines

Cleaning and Changeover Optimization

Quick-Change Components

- Modular Designs: Swappable feed screws, rotors, or troughs

- Tool-less Disassembly: Clamps instead of bolts for fast access

- Standardized Interfaces: Uniform connections between modules

Cleaning Protocols

- Dry Cleaning: Brushes, vacuums, and purge systems for product changeovers

- Wet Cleaning: Designed-in spray balls and drain points for wash-down

- Inspection Points: Clear sight glasses or camera ports for cleanliness verification

Material Purge Strategies

- Sequential Flushing: Dedicated purge materials with known flow properties

- Air Scouring: High velocity air streams to clear residual powder

- Vibration-assisted Emptying: Ensure complete material discharge

Performance Monitoring and Continuous Improvement

Key Performance Indicators

- Feed Consistency: Standard deviation of feed rate <1% of mean

- Material Utilization: >99.5% of fed powder reaching dies

- Changeover Time: <30 minutes for similar material switches

Data Analytics

- Trend Analysis: Correlate feeder performance with tablet quality metrics

- Root Cause Investigation: Link feeder variations to specific press issues

- Prescriptive Maintenance: Algorithm-driven service scheduling

Benchmarking

- Throughput Efficiency: Actual output vs. theoretical maximum

- Energy Consumption: kWh per kilogram of fed material

- Uptime Percentage: >95% availability during production runs

Regulatory Considerations

Documentation Requirements

- IQ/OQ/PQ Protocols: Comprehensive validation documentation

- Material Traceability: Full chain from feeder to finished tablet

- Change Control: Document all modifications to feeder system

GMP Compliance

- Surface Finishes: Meet sanitary design standards

- Cleanability Verification: Swab test results for residue levels

- Lubrication Systems: FDA-approved lubricants where needed

Data Integrity

- Audit Trails: Record all feeder parameter changes

- Access Controls: Secure access to critical settings

- Electronic Records: 21 CFR Part 11 compliant data systems

Emerging Technologies in Feeder Optimization

Smart Feeder Systems

- AI-based Control: Machine learning algorithms adapting to material variations

- Digital Twins: Virtual models predicting feeder behavior

- Augmented Reality: Guided maintenance and troubleshooting

Advanced Materials

- Self-cleaning Surfaces: Hydrophobic or oleophobic coatings

- Wear-resistant Alloys: Extended service life in abrasive applications

- Composite Components: Lightweight yet durable feeder parts

Integrated Quality Systems

- In-line NIR: Real-time composition monitoring during feeding

- Particle Imaging: Continuous size distribution verification

- Density Measurement: Nuclear or microwave-based mass flow confirmation

Conclusion

Optimizing feeder systems in large tonnage tablet presses requires a multifaceted approach combining mechanical design, material science, process control, and advanced analytics. By systematically addressing each component of the feeding system—from powder characterization to smart control algorithms—manufacturers can achieve significant improvements in productivity, quality, and operational efficiency. The most successful implementations combine proven engineering principles with cutting-edge technologies, all while maintaining rigorous compliance with pharmaceutical manufacturing standards. Continuous monitoring and data-driven adjustments ensure feeding systems remain optimized even as material characteristics or production requirements evolve over time.

Teléfono

Teléfono

Comentario

(0)